Henny Penny first introduced commercial pressure frying to the food service industry more than 50 years ago. Frying under pressure enables lower cooking temperatures for longer oil life and faster cooking times to meet peak demand. Pressure also seals in food’s natural juices and reduces the amount of oil absorbed into the product.

Today, Henny Penny pressure fryers continue to lead the industry in performance, durability, and innovation. In the Food Equipment industry, Henny Penny and DSL have a very good relationship. DSL has been doing distribution and servicing in Western Canada for a very long time around 100 Years. We have the expertise to do proper product distribution, installation, training, and servicing along with lots of product categories and models of reputed brands.

Powerful, high-efficiency immersed heating elements generate fast temperature recovery without sacrificing energy savings. Large loads are cooked evenly and handled easily with the patented counterbalance lift system.

Henny Penny pressure fryers have a built-in filtration system that filters and returns hot frying oil in minutes. No separate pumps and pans, no handling hot oil.

Control Panel

The Computron™ 8000 control features automatic, programmable operation, as well as energy-saving, filtration, and cook management functions.

- 10 programmable cook cycles

- Melt mode, Idle mode, Clean-out mode

- Water detection alert

- Load compensation

- Proportional control

- Optional filter prompt and customizable filter tracking

- 16-character digital display with multiple language settings

Standard Features

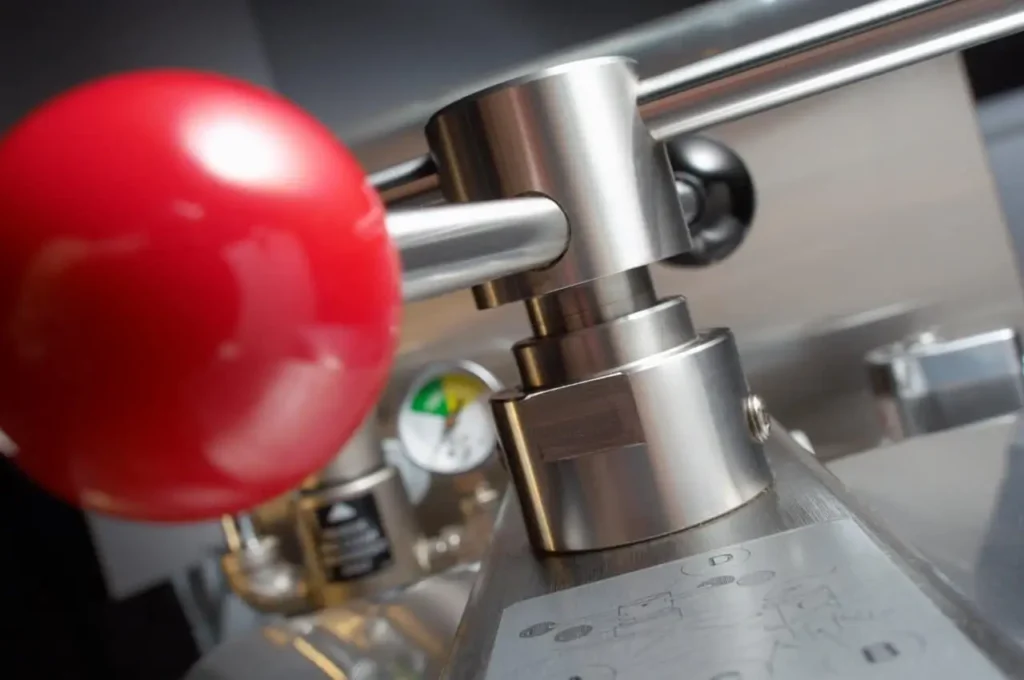

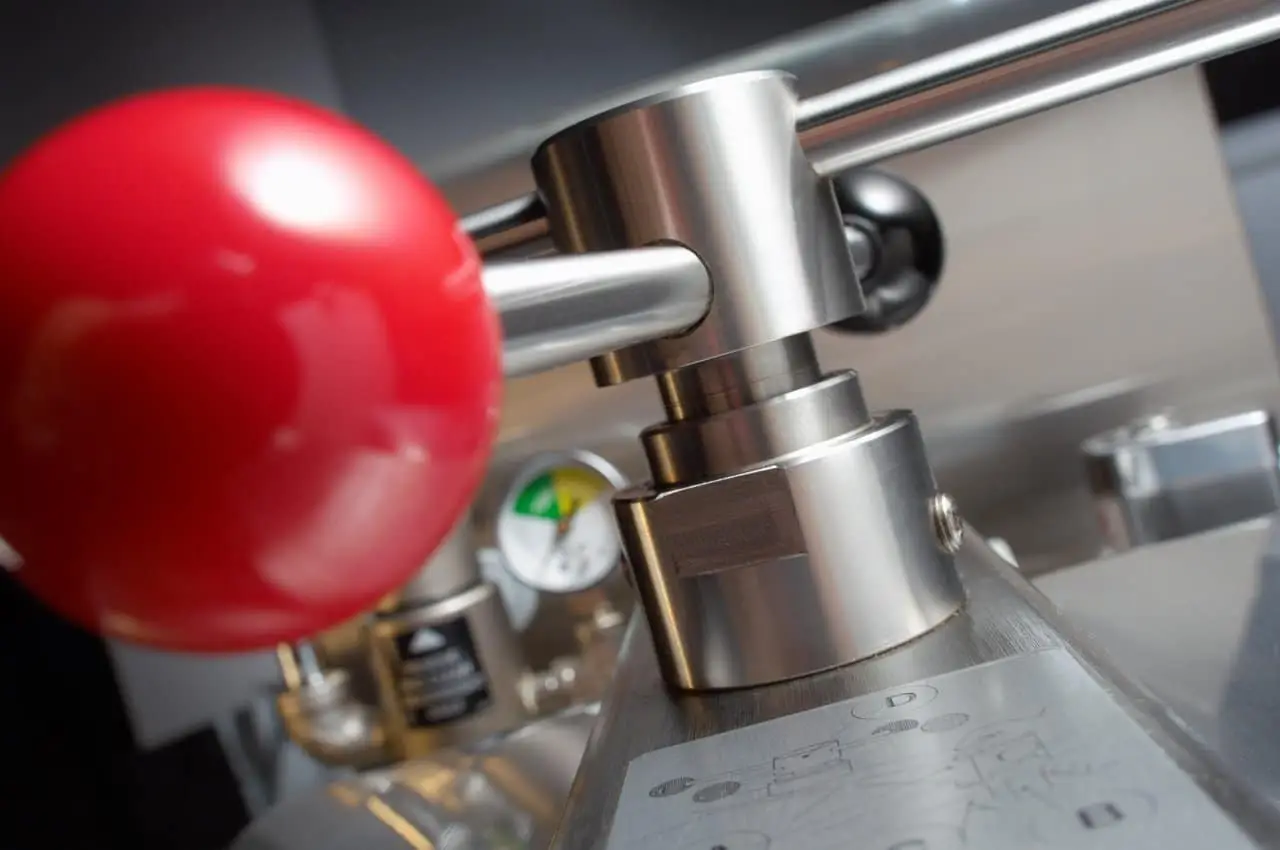

- Patented counter-balanced lid lift and lock system for easy loading and unloading

- Heavy-duty stainless steel fry pot with 7-year warranty

- Rectangular fry pot design promotes turbulence for even cooking

- Fry pot is fully insulated for energy-efficient operation

- Gas – 4 high-efficiency burners with solid state ignition / Patented draft-induced heat transfer technology

- Electric – High-efficiency heating elements generate fast recovery and energy savings

- Cold zone below burners helps extend oil life

- High-limit temperature protection

- Lid remains in locked position until pressure reaches 1 psi

- Built-in filtration system

- Raised edge on deck reduces spills

- Stainless steel construction for easy cleaning and long life

- 4 heavy-duty casters, 2 locking

Accessories & Options

Accessories shipped with the unit

- Loading carrier

- Basket configuration, choose one:

- Full basket—4 flat wire baskets, 1 wire rack cover, rack handle

- Half-size rack—4 wire racks, 1 wire rack cover, rack handle

- Stirrer and drain clean-out rod

- Filter screen and 2 PHT filter envelopes

Accessories and options available separately

- Fryer Shortening Shuttle®

Choose one:

- Filter rinse hose OR

- Direct Connect shortening disposal