Understanding the Main Difference and Benefits for Your Commercial Kitchen

In the competitive world of commercial kitchens, choosing the right foodservice equipment can make a huge difference in both the quality of your fried foods and your bottom line. Among the key decisions is selecting between a pressure fryer vs deep fryer. Both methods can produce delicious fried chicken, french fries, and other popular food items, but how each fryer cooks food and affects operating costs, oil quality, and overall results varies significantly.

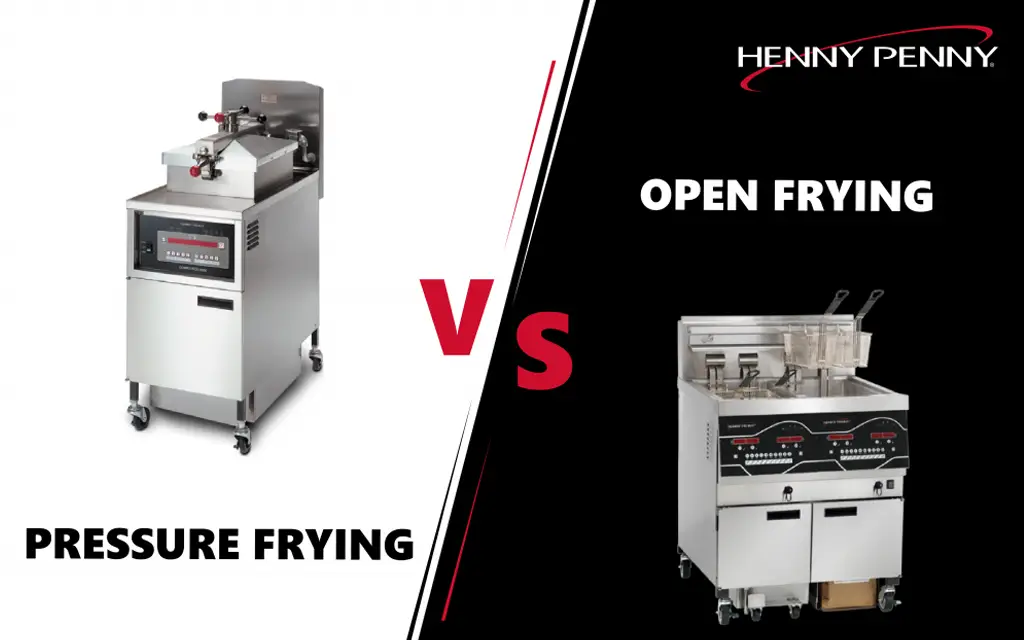

The Main Difference: Pressure Frying vs Conventional Open Frying

The main difference between a pressure fryer and a deep fryer lies in the pressurized cooking environment. While a deep fryer (or open fryer) operates at atmospheric pressure with a lid open or loosely covered, a pressure fryer uses a sealed chamber. When the pressure increases inside this chamber, it creates a unique environment for cooking.

Pressure frying involves using a commercial pressure fryer—a specialized piece of foodservice equipment designed for pressurized cooking. As the food cooks, the generated steam inside can’t escape, allowing pressure to build. This results in a lower temperature needed to achieve the same results compared to open frying. In contrast, a deep fryer relies on open frying, which typically requires a higher temperature to fully cook the food.

How Pressure Fryers Cook Food Differently

A pressure fryer works similarly to pressure cookers: once the lid open position is locked and sealed, the hot oil heats the food items. As pressure increases, the boiling point of water inside the food rises, allowing natural juices and flavours to remain locked in. This pressurized cooking environment results in less moisture loss, so fried foods like bone in chicken remain juicy and flavorful on the inside while maintaining a crisp exterior.

In conventional open frying, excess oil and less moisture management can lead to drier meats and potentially less flavourful outcomes. Since there is no pressure sealing the environment, oil and vapour easily escape, potentially increasing operating costs due to reduced exposure to controlled conditions. The difference is not just theoretical; it can mean a healthier product, better flavour, and more efficient use of resources in a pressure fryer.

The Benefits of Pressure Frying

1. Improved Flavour and Quality:

Pressure frying seals in natural juices, preventing the loss of moisture that can occur in open frying. This is especially beneficial for fried chicken and other bone in chicken dishes, as the meat stays tender and juicy. The controlled environment also avoids cold spots, ensuring even cooking throughout the fry pot.

2. Faster Cooking and Less Energy:

Because pressure fryers cook at a lower temperature without sacrificing quality, the cooking time is often shorter than traditional open fryer methods. The presence of pressure speeds up the heat transfer process, resulting in faster cooking. Additionally, cooking at a lower temperature generally means using less energy, helping you save less money in the long run.

3. Better Oil Life and Quality:

One of the biggest costs associated with frying is cooking oil. A commercial pressure fryer creates a sealed environment that leads to reduced exposure of the oil to air. Less oxidation and fewer impurities mean you can extend oil life and maintain oil quality for longer. This translates to less oil consumption, lower operating costs, and less frequent oil changes. Using less oil and preserving oil life also reduces your actual cost per batch of fried foods.

4. Healthier Product:

While “healthier” is a relative term when discussing fried items, pressure frying can yield a healthier product compared to traditional open frying. Because the food is cooked more quickly and evenly, it absorbs less oil. With less oil absorbed, the finished product can be lighter, less greasy, and potentially more appealing to consumers who are conscious of their dietary choices.

5. Additional Safety Features:

Modern commercial pressure fryer models often include additional safety features. These safety features ensure that the pressurized cooking environment is secure. For instance, leading brands like Henny Penny have developed advanced systems that prevent the fryer lid from opening until the pressure is released, reducing the risk of dangerous splatters or sudden escapes of hot oil. These systems control when you can have the lid open, enhancing staff safety.

Pressure Frying vs Deep Frying for Different Foods

Fried chicken is arguably the star of pressure frying, but it’s not the only option. Many food items, from french fries to fish and other proteins, benefit from this method. While open frying can achieve a crunchy exterior, especially for thin items like french fries, it may struggle to keep thicker cuts of meat as juicy as a pressure fryer can.

For restaurants focused on fried chicken or similar menu items, the pressure fryer can make a huge difference in both quality and yield. On the other hand, if your menu primarily features lighter items where a crunchy exterior is key, a deep fryer may still be suitable.

Operating Costs and Longer-Term Savings

By reducing the higher temperature requirements and lowering energy usage, pressure frying can save you less money over time. The oil lasts longer, you use less oil overall, and your staff doesn’t need to manage as many frequent oil changes. The actual cost of running a commercial pressure fryer may be lower than you think, especially when considering operating costs spread over months or years.

Additionally, less oil usage means fewer oil deliveries and less storage space needed for extra drums of oil. This simplification of operations helps keep your kitchen running smoothly and reduces waste, leading to further savings in the long run.

Safety and Maintenance Considerations

Both pressure fryers and deep fryers involve hot oil, so safety is always a priority. The pressurized cooking environment in a pressure fryer demands well-engineered safety features. Quality manufacturers like Henny Penny have designed their fryers to ensure that the lid open sequence cannot occur under pressure, preventing accidents.

Maintenance is also essential for ensuring your fryer’s longevity. Regular cleaning, oil filtration, and periodic checks of the fryer’s pressure systems are necessary for optimal performance. Proper care will keep your commercial pressure fryer running smoothly, extending its lifespan and getting the most out of your investment.

Finding the Right Balance for Your Commercial Kitchen

When choosing between a pressure fryer vs deep fryer, consider your menu, volume, and quality standards. If your commercial kitchens specialize in succulent, juicy fried chicken, a pressure fryer may be the best choice. This equipment’s ability to pressure cooking at a lower temperature, seal in natural juices, and deliver consistently flavorful results can elevate your brand and please your customers.

If your menu leans more towards crisp, lighter fried foods, like battered appetizers or french fries, a deep fryer might still serve you well. For many operations, incorporating both methods—using a pressure fryer for bone in chicken and a deep fryer for sides—could offer the best of both worlds.

Conclusion: The Value of Pressure Frying

In the debate of pressure fryer vs deep fryer, there’s no one-size-fits-all answer. However, the appeal of pressure frying—from faster cooking, extended oil life, improved flavour, and less oil absorption—makes it a compelling option for commercial kitchens looking to serve outstanding fried foods.

Adopting a commercial pressure fryer can lead to less energy consumption, lower operating costs, and a more consistent, healthier product. Whether you’re focused on bone in chicken, experimenting with new food items, or simply seeking to improve your kitchen’s efficiency and product quality, a pressure fryer could be the transformative tool you need in your culinary arsenal.