How Henny Penny’s Equipment Lowers Your Environmental Footprint

In today’s world, sustainability in food production and the food industry isn’t just a trend; it’s a necessity. Global greenhouse gas emissions from food systems contribute nearly one-third of all emissions worldwide, emphasizing the urgent need for sustainable food systems and sustainable agricultural practices.

In commercial kitchens and restaurants, achieving a sustainable food system means adopting energy-efficient, waste-reducing equipment to meet the growing demand for food security and environmental sustainability. Henny Penny’s innovative solutions, like their low-oil volume fryers and boilerless steam combi ovens, help reduce waste and contribute to more sustainable food production.

Let’s dive into how Henny Penny’s equipment is paving the way toward a greener food industry and reducing the environmental impact across the entire value chain.

Embracing Energy Efficiency with Low-Oil Volume Fryers

Energy efficiency is critical in reducing greenhouse gas emissions, and Henny Penny’s low-oil volume fryers are designed with this in mind. Traditional deep fryers consume large amounts of oil and energy, creating both environmental and financial waste. Henny Penny’s fryers, such as the Velocity Series Fryer, have been engineered to use up to 40% less oil than standard models. This reduction in oil usage not only cuts down on waste but also contributes to significant cost savings for businesses, while reducing the environmental footprint of food production systems.

By extending the lifespan of the oil and reducing oil disposal needs, Henny Penny’s fryers help businesses meet their sustainability goals while lowering operational costs. In a world where food sustainability and food waste reduction are top priorities, these fryers offer an eco-friendly solution for foodservice providers striving to align with sustainable development goals.

Minimizing Water Usage with Boilerless Steam Generation

Water usage in commercial kitchens contributes to the environmental impact of food production systems. Henny Penny’s boilerless steam generation technology, featured in their FlexFusion combi ovens, offers an innovative solution for conserving water. This system generates steam only as needed, significantly reducing water consumption compared to traditional boiler-based steam systems. Less water use not only benefits the environment but also reduces lime buildup, which means less maintenance, fewer chemical cleaners, and a longer lifespan for the equipment.

Incorporating boilerless technology into the cooking process allows kitchens to meet consumer demand for sustainable food options without compromising on product quality. Henny Penny’s FlexFusion Platinum Combi Oven with FlexiRack also maximizes capacity, ensuring that kitchens can produce food efficiently while adhering to water management practices that support environmental sustainability.

Sustainable Production Through Efficient Design

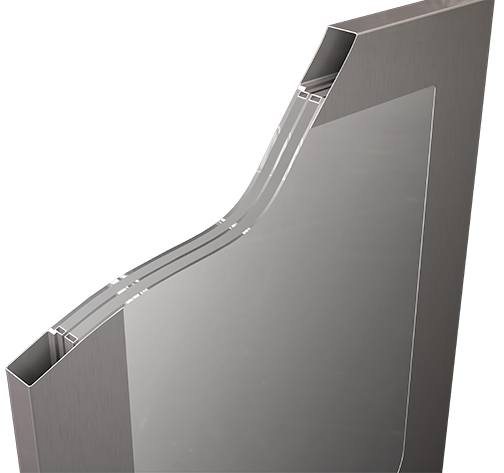

The design of Henny Penny’s equipment prioritizes not only functionality but also sustainable development. Their triple-pane glass doors and LED lighting are examples of energy-efficient features that reduce the overall environmental footprint of food service equipment. The triple-pane glass doors provide insulation that minimizes heat loss, reducing the energy required to maintain cooking temperatures, while the LED lighting uses up to 80% less energy than conventional lighting. These features reflect a holistic approach to sustainability that extends from product development to the kitchen floor.

Choosing energy-efficient equipment is essential in the context of climate change, as it directly reduces the greenhouse gas emissions associated with the food sector. As Henny Penny’s products demonstrate, reducing energy consumption at each stage of food production helps lower the impact on natural resources, ensuring a sustainable food supply for future generations. Read More About: How Long Do Combination Ovens Typically Last?

Reducing Waste with Advanced Cleaning Systems

One of the most pressing challenges in creating a sustainable food system is food waste. According to reports, one-third of all food produced is lost or wasted, contributing to the loss of valuable resources like water, energy, and agricultural land. Henny Penny’s WaveClean system minimizes waste in the kitchen by automating the cleaning process with a single, environmentally friendly cartridge. This system significantly reduces water usage and chemical waste, making it a valuable tool for foodservice providers committed to sustainability practices and food safety.

By keeping the equipment clean without the need for excessive water or chemicals, Henny Penny’s WaveClean system directly addresses sustainability in food industry practices. It also supports food safety and hygiene standards, an essential component of food production systems that aim to reduce food losses and protect future generations from food insecurity.

Digital Connectivity for Real-Time Sustainability Tracking

Sustainable food production today relies on advanced data tracking to optimize energy efficiency and waste reduction across the food system. Henny Penny’s GreenInside feature integrates digital connectivity into their equipment, allowing kitchens to monitor energy and water usage in real time. Through the Connected Kitchen platform, businesses can access insights on their energy consumption, helping them make data-driven decisions that align with sustainability goals.

This feature empowers kitchen operators to set benchmarks for energy efficiency, monitor their environmental footprint, and identify areas for improvement in real time. Such data-driven decision-making enables businesses to improve food sustainability practices and contribute to a sustainable food system, creating a positive impact on both local levels and the global food systems.

Meeting the Growing Demand for Sustainable Food

With the global population projected to reach nearly 10 billion by 2050, food production systems must adapt to support sustainable diets and minimize environmental impact. Henny Penny’s equipment offers foodservice providers the tools needed to produce food responsibly, reduce waste, and manage resources efficiently. In the face of rising consumer demand for sustainable food and environmental sustainability, investing in energy-efficient, waste-reducing equipment like Henny Penny’s is a step toward achieving a more sustainable food industry.

A Greener Future for Food Service

Henny Penny’s commitment to sustainability in food production aligns with the food industry’s need for efficient, eco-friendly solutions. By incorporating features like low-oil volume fryers, boilerless steam generation, WaveClean, and GreenInside, Henny Penny provides foodservice providers with the means to reduce greenhouse gas emissions, conserve resources, and lower their environmental footprint across the entire supply chain.

For restaurants and kitchens focused on sustainable development, Henny Penny’s equipment is more than just a tool—it’s an investment in the future of our planet. Embracing these sustainability practices not only helps meet today’s consumer demand for eco-friendly options but also supports the broader goals of sustainable food systems, food security, and environmental responsibility.