Proper maintenance of your commercial espresso machine is essential for consistent performance and coffee quality. This article covers daily, weekly, and semi-annual maintenance tasks for commercial espresso machine maintenance to keep your machine in top shape, help you avoid breakdowns, and ensure every cup satisfies your customers.

Key Takeaways

- Regular maintenance alongside cleaning are important for optimal espresso machine performance, ensuring high-quality coffee and extending the machine’s lifespan.

- Daily and weekly maintenance tasks, including purging group heads and cleaning steam wands, are crucial for preventing blockages and maintaining coffee flavour.

- Participating in a Preventative Maintenance Program helps businesses minimize breakdowns, enhance productivity, and guarantee consistency in coffee quality.

Importance of Regular Maintenance

Routine maintenance ensures your machine lasts longer and consistently produces high-quality coffee. Daily maintenance prevents damage and maintains coffee quality, which is crucial for any business. Regular upkeep, particularly commercial espresso machine maintenance, extends the machine’s life and ensures optimal performance and consistent coffee quality.

A preventative maintenance program, such as the one from DSL can further enhance your machine’s reliability. These programs offer scheduled maintenance tasks, including commercial espresso machine maintenance, to prevent breakdowns and extend your machine’s lifespan. Inspections and necessary repairs help maintain consistent coffee quality and minimize service disruptions.

These practices will save you from costly repairs and keep your customers happy with every cup.

Benefits of Regular Cleaning

Cleaning is the unsung hero of espresso machine maintenance. It prevents mineral and oil buildup that can alter coffee taste, ensuring every brew is of the highest quality. A regular cleaning routine prevents grime accumulation, helping your machine last longer and operate efficiently.

Well-filtered water and consistent cleaning solutions improve espresso quality by minimizing dissolved minerals affecting the flavour. Clean the group head and steam wand regularly to avoid rancid flavours and blockages.

Regular maintenance ensures your espresso machine performs at its best daily.

Impact on Coffee Taste

Keeping the machine clean avoids flavour alterations from oil and mineral accumulation. Purging the steam wand and maintaining the water filtration system preserve the espresso’s pure taste by preventing scale buildup.

Coffee with a metallic or off-taste could result from improper maintenance. Cleaning the group head, portafilter, and other components ensures that no old grounds or residues affect the flavour of your brew.

Investing time cleaning and maintaining your coffee machine guarantees every cup of espresso reflects your commitment to quality.

Daily Maintenance Tasks

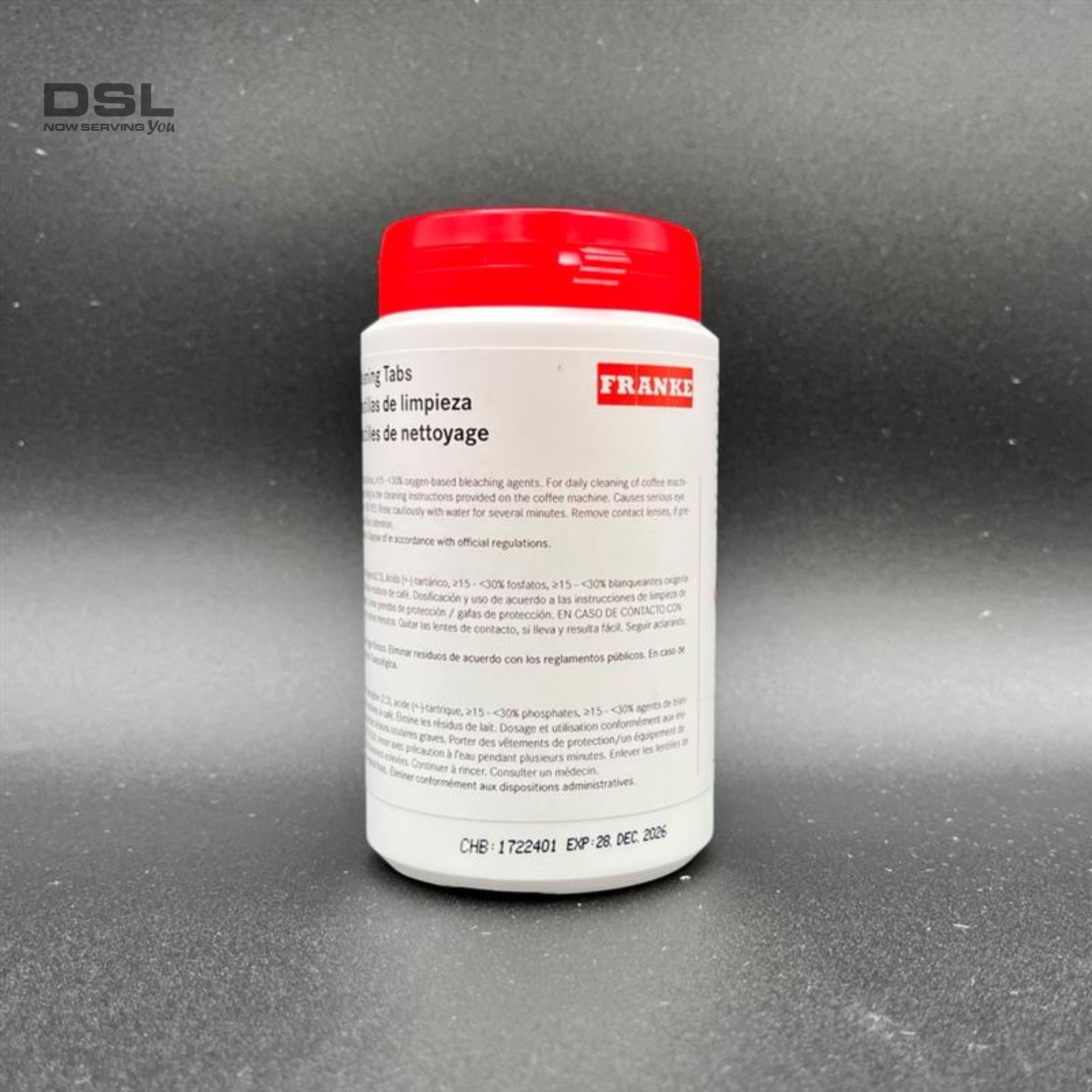

Daily tasks form the foundation of a well-maintained espresso machine. Tasks include washing the drip tray, portafilter, filter baskets, and milk pitcher with warm, soapy water and drying them to prevent water spots. Empty and regularly clean the drip tray, especially when the indicator is visible. It’s also good to use tablets like Franke Espresso Machine Cleaning Tablets to ensure a thorough cleaning.

Purging the Group Head

Purging the group head after each shot maintains espresso quality. Flush the group head with water for 1-3 seconds to remove accumulated coffee grounds and oils. Include a quick water backflush and wipe down the dispersion screen daily.

After reassembling the portafilter, flush the group head for 10 seconds. This keeps the filter basket clean and prepares it for the next shot.

Cleaning the Steam Wand

The steam wand is critical, and keeping it clean is paramount. After each use, purge and wipe down the steam wand to prevent milk residue accumulation and blockages. Purge the steam wand by placing a microfiber towel over the end and turning it on for 1-2 seconds before and after steaming milk. Immediately clean and purge it for another 1-2 seconds to ensure no residue is left.

Regular steam wand cleaning ensures proper functionality and maintains milk froth quality. The cleaning process involves selecting water, positioning it over a cup or drip tray, pressing start/cancel, waiting 3-5 seconds, and wiping with a damp cloth.

These steps prevent blockages and keep your espresso machine in top condition.

Wiping Down the Machine

Daily wiping down of the espresso machine maintains coffee quality and hygiene. Use a damp cloth to wipe down the machine, especially in areas with coffee splashes and milk spills. This simple task prevents grime buildup and keeps your machine looking and functioning like new.

Weekly Deep Cleaning

While daily maintenance keeps your espresso machine running smoothly, weekly deep cleaning tackles more stubborn residues and buildup. Perform a deeper clean weekly to ensure all components are thoroughly cleaned and maintained. Avoid abrasive cleansers and scouring pads, which can damage the machine’s surfaces. Opt for appropriate coffee detergents and wear gloves to protect your hands during cleaning.

During weekly cleaning, perform a full detergent backwash, thoroughly clean the grinder and steam wand, and clean the drain box and line, replacing any worn drain lines. Dedicating weekly time to deep cleaning ensures your espresso machine remains in peak condition, delivering the best coffee to your customers.

Backflushing the Espresso Machine

Backflushing removes coffee oil residues and maintains hygiene. To backflush the espresso machine, insert a blank basket with Cafiza into the portafilter, lock it into the machine, and run for five seconds.

Stop, expel the water, and repeat three more times. Cafiza is the standard detergent for cleaning espresso machines, effectively breaking down coffee oils and dissolving quickly in water. Scrub the group screen and rubber gasket with a brush before backflushing to ensure no residual buildup interferes with cleaning.

Regular backflushing keeps your espresso machine clean and free from harmful residues. Backflushing as often as possible maintains the machine’s performance. Making backflushing part of your weekly routine extends your espresso machine’s life and ensures it operates at its best.

Cleaning the Drip Tray and Water Tank

The drip tray and water tank are often overlooked but crucial parts of your espresso machine. Empty and clean the water tank and drip tray using warm, soapy water to prevent residue buildup. Rinse and dry thoroughly. Avoid abrasive cleansers or scouring pads to prevent damage to these parts.

Regular drip tray and water tank cleaning maintains hygiene and optimal machine performance.

Soaking Portafilters and Baskets

Soak portafilters and baskets in hot water to dissolve accumulated coffee oils and residues. Cleaning tablets during soaking enhances the removal of stubborn buildup on metal components. Regular maintenance, including soaking, ensures optimal flavour in the coffee served.

Detergent and hot water effectively clean the portafilter and filter basket. Soaking your espresso machine parts regularly keeps them clean and free from residues that could affect coffee flavour.

Semi-Annual Maintenance

Semi-annual maintenance keeps your espresso machine in top condition and ensures quality espresso. Every six months, perform in-depth maintenance tasks such as descaling the machine, replacing water filters, and inspecting and cleaning grinders.

Products like Urnex Biocaf and Grindz are recommended for cleaning the grinder and steam wand every six months. Adhering to these semi-annual tasks prevents significant issues and keeps your machine running smoothly.

Descaling the Machine

Descaling your espresso machine every six months prevents scale buildup that can affect performance. If your machine sputters or experiences flow issues, it may need descaling. Refer to the owner’s manual for specific instructions.

Fill the tank with 0.5L of water and the recommended descaling solution; avoid vinegar. Select the descaling setting on the machine and follow the display instructions to complete the process.

After descaling, rinse the reservoir thoroughly. Refill it with fresh water and run another cycle to flush the system. Descaling ensures your machine runs efficiently and produces high-quality coffee.

Replacing Water Filters

Replacing the water filter every six months maintains your espresso machine. This ensures clean water and reduces scale accumulation, affecting the machine’s performance. Change the water filter every six months.

Maintaining water hardness between 35 and 85 ppm for optimal espresso machine performance. Regularly replacing the water filter protects your machine and ensures your coffee tastes its best.

Inspecting and Cleaning Grinders

Inspecting and maintaining grinders regularly ensures consistent grind quality, directly affecting espresso extraction. Inconsistent grinder settings can lead to variations in espresso shots, affecting both flavour and consistency.

By inspecting and cleaning grinders every six months, you can preserve the quality of your espresso and prevent any issues that could arise from neglected grinders. Ensuring your grinders are in top condition is a key part of delivering exceptional coffee to your customers.

Annual Maintenance Checklist

An annual maintenance checklist is crucial for prolonging the lifespan and efficiency of commercial espresso machines. Essential maintenance tasks vary by manufacturer and use frequency. Different espresso machine brands may have specific maintenance requirements depending on their design and operational demands.

Following the annual maintenance checklist ensures optimal performance and reduces the risk of costly repairs. This checklist allows you to keep your espresso machine running smoothly and efficiently for years.

Replacing Group Gaskets and Screens

Replacing group gaskets and screens annually is a key part of regular maintenance for optimal machine performance. To replace these parts, use a stubby screwdriver to remove the group head screen and a 90° hook pick to help replace the gaskets effectively.

Lubricate the new gasket with a food-safe lubricant like DOW 111 to ensure proper sealing. Combining the annual gasket and screen replacement with adequate lubrication and tools ensures efficient and effective maintenance.

Full Machine Inspection

A complete machine inspection identifies wear and tear and ensures all components function optimally. Performing semi-annual maintenance tasks, such as descaling and replacing water filters, helps address potential issues before they become serious problems.

Inspecting and cleaning grinders is crucial for maintaining consistent grind quality and preventing machine wear. Scheduling professional servicing ensures that complex maintenance tasks are handled correctly, extending the machine’s life.

Professional Servicing

Scheduling professional servicing is essential for handling complex maintenance tasks and ensuring optimal performance of espresso machines. Professional servicing helps businesses avoid disruptions and maintain high-quality coffee production through regular maintenance.

Implementing a preventative maintenance program can systematize servicing to enhance machine longevity and performance. An annual maintenance checklist includes crucial tasks such as replacing group gaskets and screens and conducting a full machine inspection.

Troubleshooting Common Issues

Before:

Even with diligent maintenance, common issues can still arise with espresso machines. Addressing these problems promptly can prevent more significant headaches or machine breakdowns. Scale buildup, for example, can prevent water flow and negatively impact the machine’s functionality. Always check that the espresso machine is properly turned on, as malfunctioning may be as simple as a power issue. Turning off the water lines can also prevent the espresso machine from operating correctly.

After:

Common issues with espresso machines include:

- Scale buildup can prevent water flow and negatively impact the machine’s functionality.

- Poor water quality can cause scale buildup, shortening the espresso machine’s life.

- The machine is not correctly turned on, which may be as simple as a power issue.

- Water lines being turned off, which can prevent the espresso machine from operating correctly.

Addressing these problems promptly can prevent more significant headaches or machine breakdowns.

Many minor issues are easily fixed with adjustments or parts replacement. However, complex repairs and significant problems often require the expertise of a professional technician. Scheduling regular professional servicing can prevent minor issues from escalating into substantial machine breakdowns.

If you are unsure about your machine’s power controls, refer to the manual for guidance. You can proactively address common issues to keep your espresso machine running smoothly and efficiently.

Low Water Flow

Low water flow can be caused by mineral buildup from hard water deposits on the spray head. If the spray head is clogged, cleaning it or soaking it in a hot cleaning solution is essential. Low water flow in commercial espresso machines can significantly impact performance and coffee quality.

Regularly descaling and using filtered water can prevent this issue and ensure your machine operates at its best.

Inconsistent Espresso Shots

Maintaining grinders is essential for ensuring consistent grind quality, directly impacting the flavour and extraction of espresso shots. Applying the correct tamping pressure is crucial for uniform extraction, as it affects water flow through the coffee grounds. Proper machine calibration helps maintain accurate brew temperature and pressure, ensuring each shot remains consistent.

Optimized grinder settings, correct tamping pressure, and calibrated machines create a foundation for exceptional espresso consistency.

Steam Wand Blockages

Keeping the steam wand clean ensures smooth operation and prevents blockages. Milk residue can accumulate inside the steam wand, causing blockages that hinder performance. After each use, purging and wiping down the steam wand helps to eliminate milk residue and prevent buildup.

Regularly inspecting and maintaining the steam wand ensures optimal performance and avoids blockages.

Preventative Maintenance Program

A Preventative Maintenance Program is an excellent way for businesses to maintain their espresso machines efficiently. DSL offers a comprehensive preventative maintenance program to help businesses achieve this goal.

By participating in such a program, you can ensure that your espresso machine operates at peak performance and extend the machine’s lifespan.

Overview of the Program

DSL’s Preventative Maintenance Program aims to ensure optimal performance and minimize downtime. The program includes scheduled maintenance tasks, regular inspections, and repairs to keep your espresso machine running smoothly.

By following the program’s instructions, you can maintain your machine’s efficiency and reliability, ensuring consistent quality in every cup of coffee you serve.

Supported Equipment Brands

The preventative maintenance program supports well-known brands, including Taylor, Franke, and Henny Penny, ensuring a broad scope of service. The program covers many espresso machines by supporting these popular brands, making it a versatile solution for many businesses.

This comprehensive support ensures that your equipment receives the best care, regardless of the brand.

Benefits for Businesses

Café owners and baristas can significantly benefit from understanding espresso machine care. The Preventative Maintenance Program helps businesses prolong the lifespan of machinery and enhance overall productivity. It ensures that the business can deliver consistent quality and service without interruption, providing peace of mind and extra time to focus on other aspects of the business.

Engaging in such a program is an investment in the future success of your café.

Summary

Maintaining your commercial espresso machine is not just about preserving expensive equipment; it’s about ensuring every cup of coffee you serve is perfect. Regular cleaning, daily and weekly maintenance tasks, semi-annual check-ups, and an annual maintenance checklist are all crucial in keeping your machine running smoothly. By following these tips, you can increase the life of your machine, avoid costly repairs, and deliver consistently high-quality coffee to your customers.

Incorporating a Preventative Maintenance Program, such as the one offered by DSL can further enhance your machine’s performance and reliability. Following the detailed tips and guidelines in this post, you can master the art of espresso machine maintenance and ensure your café remains a favourite spot for coffee lovers. Here’s to serving the perfect espresso, one well-maintained machine at a time!

Frequently Asked Questions

What does DSL’s Preventative Maintenance Program aim to achieve?

DSL’s Preventative Maintenance Program aims to optimize performance and significantly reduce downtime, allowing you to maintain efficiency and productivity. Prioritize this program for a smoother operation!

Which brands of equipment does the Preventative Maintenance Program support?

The Preventative Maintenance Program supports Taylor, Franke, and Henny Penny equipment, ensuring optimal performance and longevity for your investment. Keep your equipment in top shape and reap the rewards!

What are the benefits of the Preventative Maintenance Program?

Implementing a Preventative Maintenance Program is a game-changer, as it not only extends the lifespan of your machinery but also boosts overall productivity. Embrace this strategy to ensure your operations run smoothly and efficiently!

How does the Preventative Maintenance Program affect business operations?

A Preventative Maintenance Program is essential for maintaining consistent quality and service, allowing your business to operate smoothly without disruptions. Implementing this program can enhance efficiency and reliability, ultimately driving success.

Why is regular maintenance necessary for espresso machines?

Regular maintenance is essential for your espresso machine. It extends its lifespan, ensures peak performance, and keeps your coffee tasting exceptional. Invest in your machine today for the best brewing results!